"Precision CNC Components. Built for Your Machine's Peak Performance."

DPQK Series Replacement Clamp for Position Indicator

PRODUCT PARAMETERS

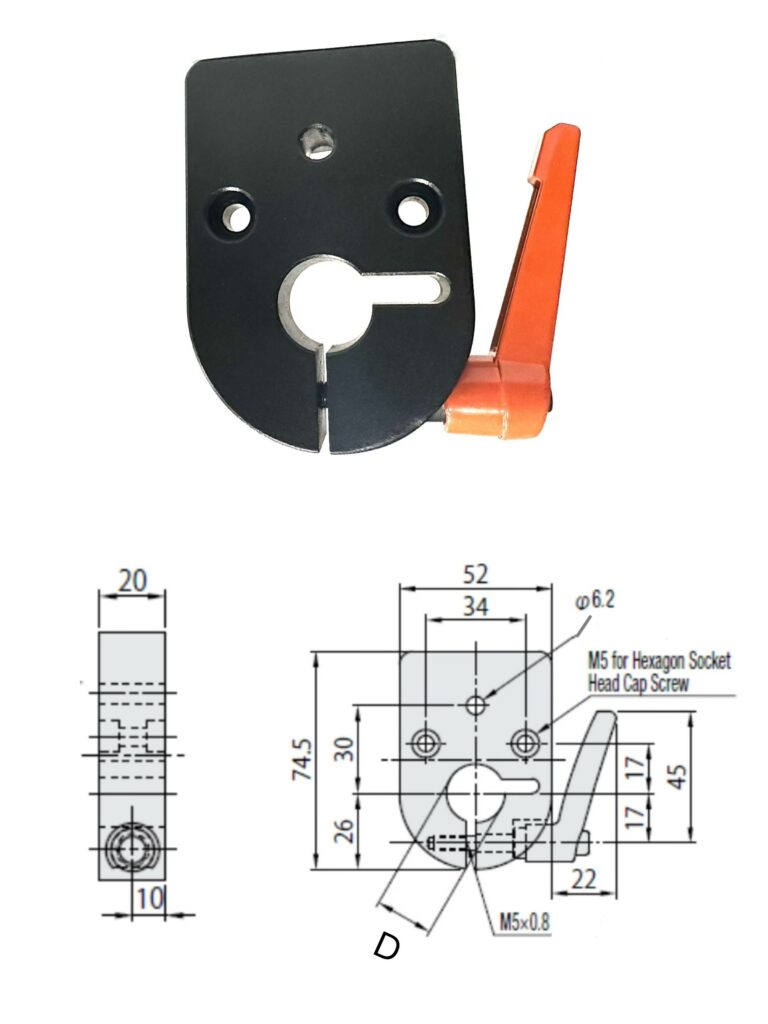

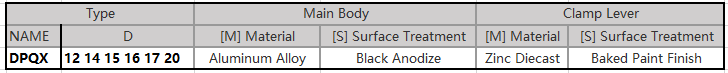

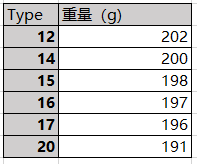

DPQK Series Replacement Vertical Handle Clamping Plate - Precision Mounting Solution for CNC Digital Readout (DRO) Counters

- Model: DPQK Series Replacement

- Material: Aluminum Alloy

- Finish: Black Anodized

- Function: Quick clamping and release

- Compatibility: Direct replacement for original DPQK series clamping plates used with CNC Digital Readout (DRO) Counters

- Mounting Method: Screw fixation

Description

Key Points

- Perfect Drop-In Replacement: A direct, high-quality alternative to the original DPQK series clamping plate, designed to be fully compatible with your existing Digital Readout (DRO) system.

- Quick Lock/Release: Features a vertical handle for fast, tool-free clamping and release, significantly improving adjustment efficiency.

- High-Precision Machining: Made from premium aluminum alloy with CNC machining, ensuring the accuracy of mounting holes and the reliability of DRO readings

Product Description

This DPQK Series Replacement Vertical Handle Clamping Plate is the ideal solution for replacing or upgrading the mounting hardware for your Digital Readout (DRO) on CNC machinery.

As a direct alternative, it is constructed from 6061-T6 aluminum alloy and finished with a black anodized coating, offering an optimal blend of durability, lightweight performance, and a sleek, professional appearance. The standout feature is its vertical orange handle, which allows for rapid locking and unlocking with a simple, tool-free operation. This dramatically simplifies the process of adjusting the DRO’s position.

With precisely engineered mounting holes, it ensures a perfect fit with your DRO unit. This replacement clamping plate delivers a stable, reliable, and user-friendly platform for your CNC equipment’s digital readout system.

Product Advantages

- Direct Replacement: Designed as a drop-in alternative, it matches the original DPQK series in dimensions and mounting specifications for a hassle-free swap.

- Cost-Effective Solution: Offers the same level of performance and reliability as the original part at a more competitive price point.

- Effortless Operation: Handle design allows for quick, tool-free adjustments by hand.

- Guaranteed Precision: CNC machining ensures the accuracy of all mounting surfaces, which is critical for maintaining DRO measurement accuracy.

- Robust Quality: Aircraft-grade aluminum alloy offers an excellent strength-to-weight ratio, while the anodized finish enhances corrosion and wear resistance.

Applications

- CNC Lathes

- CNC Milling Machines

- Machining Centers

- Precision Measuring Equipment

- Automated Production Lines

FAQs

Make amazing 60 degree bevel cuts with our 8-1/4 in. SKILSAW Worm Drive model SPT78W-01. This saw is powered by our largest 15 amp Dual-Field high torque motor so you will make the last cut as precisely as you did the first cut. Exclusive 60 degree bevel. High torque Dual-Field motor. Legendary SKILSAW durability. Includes: SPT78W 8-1/4 In. Worm Drive SKILSAW, 24 Tooth Carbide blade and multi-functional blade wrench.

Make amazing 60-degree bevel cuts with our 8-1/4 in. SKIL Worm Drive Skilsaw model SPT78W-01. This Skilsaw is powered by our largest 15 amp Dual-Field™ high torque motor so you will make the last cut as precisely as you did the first cut. Exclusive 60-degree bevel. High torque Dual-Field™motor. Legendary SKIL durability.

Shenguan is a direct seller of CATL, LISHEN, EVE, GOTION, Narada, TAFEL, CALB, REPT and other batteries. We have fresh stock, ready for shipment. Support ODM&OEM, please contact the store customer service to provide customized requirements.

- This saw is powered by our largest 15 amp Dual-Field

- High torque motor so you will make the last cut as precisely as you did the first cut.

- Exclusive 60 degree bevel. High torque Dual-Field motor. Legendary SKILSAW durability.

- Includes: SPT78W 8-1/4 In. Worm Drive SKILSAW, 24 Tooth Carbide blade and multi-functional blade wrench.